#structural formwork

Explore tagged Tumblr posts

Text

Permanent Concrete Formwork Solutions by Santana Stud Welding

Looking for durable and efficient permanent concrete formwork systems? Santana Stud Welding offers expert solutions designed to meet the highest standards of structural integrity and performance. Trusted by leading contractors across Australia, our formwork systems ensure faster installation, reduced costs, and superior build quality.

We're proud to be listed on ServiceProfessionalsNetwork.com — connecting industry-leading services with professionals who demand the best.

#permanent concrete formwork#stud welding#Santana Stud Welding#structural formwork#construction solutions#SPN listing

0 notes

Text

Learn everything you need to know about shuttering in construction, including its various types and significance. Discover how shuttering plays a crucial role in shaping and supporting concrete structures during the construction process. Enhance your construction knowledge with insights from ShreeTMT.

#Shuttering#Construction#Concrete Structures#Types of Shuttering#Importance of Shuttering#ShreeTMT#Construction Process#Building Support#Construction Techniques#Structural Engineering#Formwork#Construction Materials#Concrete Formwork#Building Foundations#Shuttering in Construction

0 notes

Text

Enhancing Formwork Detailing: The Transformative Power of BIM Modeling for Structural Contractors

Introduction

In the realm of construction, precision and efficiency are paramount. Structural contractors are tasked with the responsibility of translating architectural designs into tangible structures, often facing challenges in formwork detailing. Formwork, the temporary mold into which concrete is poured, demands meticulous planning and execution to ensure structural integrity and cost-effectiveness. Here's where Building Information Modeling (BIM) steps in as a game-changer, revolutionizing formwork detailing processes and empowering contractors to achieve unparalleled efficiency and accuracy.

Understanding Formwork Detailing

Formwork, often referred to as shuttering, serves as the temporary mold into which concrete is poured and allowed to harden. It's a critical component in concrete construction, influencing project timelines, costs, and structural integrity. Formwork detailing involves meticulous planning and design to ensure the formwork accurately conforms to the desired shape and dimensions of the concrete element being cast. Any inaccuracies or inefficiencies in formwork detailing can lead to delays, cost overruns, and compromised quality.

The BIM Advantage

Enter Building Information Modeling (BIM), a revolutionary technology that has reshaped the landscape of the construction industry. BIM is a digital representation of the physical and functional characteristics of a building, offering a comprehensive platform for collaborative design, visualization, and simulation. When applied to formwork detailing, BIM unlocks a myriad of benefits for structural contractors:

1. Enhanced Visualization and Planning

BIM enables contractors to visualize formwork designs in a 3D digital environment, providing a clear understanding of the structure's geometry and spatial relationships. With sophisticated modeling tools, contractors can simulate various formwork scenarios, optimizing layouts for efficiency and material utilization. This level of visualization facilitates early-stage problem-solving and informed decision-making, mitigating risks and minimizing costly errors during construction.

2. Accurate Quantity Takeoffs

One of the primary challenges in formwork detailing is accurately estimating material quantities. BIM streamlines this process by generating precise quantity takeoffs based on the digital model. By extracting data directly from the BIM environment, contractors can calculate the required formwork components with unparalleled accuracy, eliminating guesswork and potential overruns. This precision not only optimizes material procurement but also contributes to cost savings throughout the project lifecycle.

3. Seamless Collaboration and Coordination

BIM serves as a collaborative platform, facilitating seamless communication and coordination among project stakeholders. Structural engineers, architects, contractors, and subcontractors can work concurrently within the BIM environment, sharing real-time updates and feedback. This integrated approach fosters transparency and alignment throughout the formwork detailing process, minimizing conflicts and maximizing productivity. By breaking down silos and fostering collaboration, BIM ensures that everyone is on the same page, driving efficiency and synergy across the project team.

DISCUSS YOUR PROJECT REQUIREMENTS WITH OUR EXPERTISE: https://prototechsolutions.com/services/bim-modeling-services/

4. Clash Detection and Risk Mitigation

Formwork detailing involves intricate geometries and complex structural configurations, increasing the likelihood of clashes and interferences during construction. BIM's clash detection capabilities enable contractors to identify and resolve conflicts proactively, preventing costly rework and delays onsite. By simulating the formwork assembly within the digital model, contractors can anticipate potential clashes and design constraints, optimizing the construction sequence and minimizing disruption. This proactive approach to risk mitigation enhances project predictability and ensures smooth execution from design to delivery.

5. Iterative Design and Optimization

BIM empowers contractors to iterate on formwork designs iteratively, exploring various alternatives and optimizations before finalizing the construction plans. By leveraging parametric modeling and computational analysis, contractors can refine formwork layouts based on performance criteria, such as load-bearing capacity, material efficiency, and constructability. This iterative design process fosters innovation and continuous improvement, allowing contractors to achieve optimal solutions that balance technical requirements with project constraints. From complex geometries to challenging site conditions, BIM equips contractors with the tools and insights needed to tackle formwork detailing with confidence and efficiency.

6. Quantification and Cost Estimation

Another noteworthy advantage of BIM in formwork detailing is its ability to facilitate accurate quantification and cost estimation. BIM software enables automated takeoff procedures, extracting precise quantities of formwork materials based on the digital model. This data-driven approach eliminates the guesswork associated with manual quantity surveys and ensures that contractors procure the right amount of materials, reducing excess inventory and minimizing project costs. Additionally, BIM enables real-time cost tracking and analysis, empowering contractors to make informed decisions throughout the construction process.

7. Sustainability and Environmental Impact

In an era of increased emphasis on sustainability, BIM offers opportunities to minimize the environmental footprint of construction activities, including formwork detailing. By optimizing formwork designs for material efficiency and reducing waste, contractors can contribute to resource conservation and waste reduction efforts. Additionally, BIM enables lifecycle assessment and analysis, allowing stakeholders to evaluate the environmental impact of formwork materials and construction processes. By making informed decisions based on sustainability criteria, contractors can align formwork practices with green building principles and industry standards.

Conclusion:

In conclusion, BIM modeling represents a paradigm shift in how structural contractors approach formwork detailing. By harnessing the power of digital technology, contractors can enhance visualization, streamline design processes, and optimize construction workflows. From improved coordination and cost estimation to enhanced safety and sustainability, the benefits of BIM in formwork detailing are manifold. As the construction industry continues to evolve, embracing BIM as a fundamental tool for formwork detailing is essential for staying competitive and delivering projects of the highest quality. By embracing innovation and leveraging BIM capabilities, structural contractors can elevate formwork detailing to new heights, paving the way for a more efficient, resilient, and sustainable built environment.

#3D BIM MODELING#revit family creation#formwork detailing services#BIM modeling#structural contractors#formwork design#formwork detailing

0 notes

Text

Vertical Aluminium Formwork System

Discover the efficiency of the Vertical Aluminium Formwork System by Finomax Scaffolding I Pvt. Ltd.—a modern, lightweight, and durable solution for fast and accurate concrete construction. Engineered for high-rise and repetitive projects, this system ensures smooth finishes, minimal maintenance, and enhanced structural integrity.

2 notes

·

View notes

Text

Step-by-Step Guide: How to Estimate Construction Costs for a New Home

Accurately estimating construction costs is essential when planning to build your dream home. Understanding and calculating these expenses helps in making informed financial decisions and avoiding unexpected surprises. Here’s a detailed, step-by-step guide on how to perform a thorough construction cost estimate for your new home.

If You Need more Information about cost Estimations, visit this Website -> https://uniqueestimations.com/new-york-construction-estimating-services/

1. Understand the Types of Construction Cost Estimates

There are different methods for estimating costs depending on the stage of your construction project:

Preliminary Estimate: An early-stage estimate based on basic information.

Detailed Estimate: Involves itemized costs for materials, labor, permits, and more.

Bid Estimate: Prepared by contractors and includes detailed pricing for project execution.

Selecting the right construction cost estimator for your project depends on your project’s complexity and accuracy needs.

2. Define the Scope of Your Project

To start estimating, it’s important to clearly outline:

Square Footage: Determine the size of the home.

Design Complexity: Architectural style and special features add complexity and cost.

Quality of Materials: Decide between budget, standard, or high-end finishes.

Having a well-defined project scope ensures that your cost estimation in construction is accurate and reliable.

3. Calculate Material Costs

Material costs often constitute a significant portion of new construction estimating costs. Factors to consider include:

Foundation Materials: Concrete, steel reinforcements, and formwork.

Structural Components: Wood, steel, or concrete framing.

Exterior Finishes: Siding, roofing materials, and insulation.

Interior Finishes: Flooring, drywall, cabinetry, and paint.

Consulting local suppliers and utilizing a construction cost estimator can help you get current pricing.

4. Account for Labor Costs

Labor expenses can vary widely based on your location, the size of your project, and the expertise required. Common roles involved include:

General Contractors: Manage the entire construction project.

Specialized Contractors: Focus on plumbing, electrical work, and HVAC installation.

Skilled Laborers: Carpenters, masons, and roofers.

Make sure to factor in wages, benefits, and potential overtime when estimating construction costs for labor.

5. Include Permits and Legal Fees

Local regulations often require permits for various aspects of home construction, including:

Building permits

Plumbing and electrical permits

Environmental impact assessments

Research the requirements in your area and budget accordingly to avoid delays or fines.

6. Don’t Forget About Utility and Site Preparation Costs

These expenses cover tasks that prepare the land for construction and ensure the home is connected to essential services:

Site Clearing and Excavation: Removing vegetation and leveling the site.

Utility Hookups: Connecting water, sewer, gas, and electricity to the property.

Driveway and Landscaping: Installing access roads and outdoor spaces.

Including these in your construction estimating costs ensures you capture the full scope of expenses.

7. Estimate Plumbing and Electrical Costs

Specialty work like plumbing and electrical installations requires detailed estimates. Utilize a new construction plumbing cost estimator to calculate the expenses for:

Plumbing: Pipes, fittings, and fixtures for kitchens, bathrooms, and outdoor areas.

Electrical Systems: Wiring, outlets, switches, and lighting installations.

These components are critical to home functionality and should be accurately budgeted.

8. Factor in Contingency Costs

Unexpected expenses often arise during construction. To mitigate financial strain, allocate:

5% to 15% of Total Budget: For unanticipated changes or issues.

Price Fluctuations: For materials and labor due to market conditions.

Including a contingency buffer is essential for realistic cost estimation in construction.

9. Use Construction Cost Estimating Tools

Modern technology makes it easier to get accurate estimates with tools such as:

Online Construction Estimators: Provide quick preliminary cost insights.

Software Programs: Offer detailed and customizable reports.

Professional Services: Hiring a professional estimator can add precision and expertise.

Selecting the right tool depends on your project’s complexity and your need for accuracy.

10. Review and Adjust Your Estimate Regularly

As your project progresses, costs may change. Continuously updating your estimate ensures that your budget remains accurate and relevant. Factors to reassess include:

Changes in material prices

Design adjustments

Project delays

Regular reviews help maintain control over your estimating construction costs and prevent budget overruns.

Final Thoughts

Accurately estimating construction costs for a new home requires careful planning, detailed calculations, and regular monitoring. By following these steps, you can confidently manage your budget and make informed decisions throughout the construction process.

If you want to read more information about construction cost Estimation Website just visit --> https://uniqueestimations.com/new-york-construction-estimating-services/

#Unique Estimations#Cost Estimation#construction cost#new home cost#resturants cost#construction labor cost estimator#cost estimation for road construction

2 notes

·

View notes

Text

"La Tourette", Square Protis, Rue Saint-Laurent, Esplanade de la Tourette, Marseille, France [1948-53] _ Architect: Fernand Pouillon _ Photos by: Spyros Kaprinis [26.05.2024].

"Remarked very positively at the time by the Ministry of Reconstruction, this project will play an important role in the subsequent attribution to Fernand Pouillon of the buildings on the quay of the port. He himself writes how this study marked an important date in the history of construction. For the first time an architect thinks as an organizer, financier, engineer, inventor and artist, and achieves the lowest construction price ever seen. During the creation of this set F. Pouillon validates his sensations and his previous knowledge, implements ideas - which he had the opportunity to forge during his collaboration with Eugène Beaudoin during the war - on town planning and the insertion of a project in an emblematic landscape, experimented with the site coordination office, the principle of which he had just invented and which no one would do without now, created the solidarity group of companies (legal structure which has continued to the present day), studies in the smallest details the costs of construction simultaneously with the design, invents the technical sheath that we know, the cast stone (hard stone plates which replace the facade formwork), insulation phonics between apartments by the insertion in wavy waves of lengths of thick fabric between the partitions, the anti-mistral spanner (a cardan system), etc. No vertical reinforced concrete framework."

4 notes

·

View notes

Text

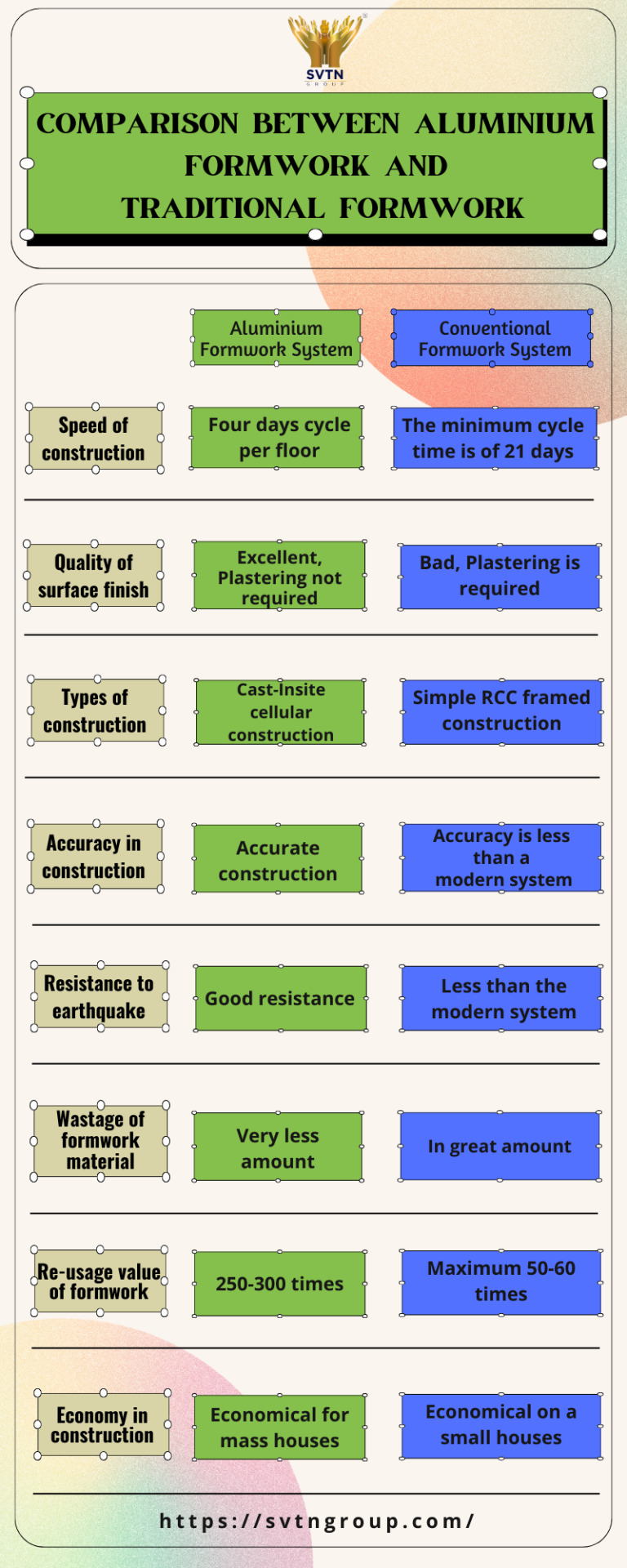

In the construction industry, formwork plays a crucial role in shaping concrete structures during the building process. Two popular formwork options used by contractors and builders are aluminium formwork and conventional formwork. Each method has its own set of advantages and considerations. In this infographic, we will explore the key differences between aluminium formwork and conventional formwork, providing you with insights to help you make an informed decision based on your construction needs.

#SVTN#SVTN construction company#aluform prefab construction#top contractors in pune#best construction company in pune#best construction work company in pune#pune best construction company#aluform construction#aluform construction technology#aluform formwork#quality construction work#quality construction works llc#Affordable and Quality Construction Works#building contractors in pune#contractors in pune#civil contractors in pune#construction technology#top civil engineering companies in pune#big construction companies in pune#building construction company in pune#top civil companies in pune#new construction companies in pune#top civil contractors in pune#leading construction companies in pune

3 notes

·

View notes

Text

In the realm of construction, the choice of building materials and techniques plays a pivotal role in determining the durability, strength, and overall quality of a structure. One such method that has stood the test of time is cast-in-situ concrete, also known as cast-in-place concrete. This construction technique involves pouring concrete directly into the formwork at the construction site, where it is allowed to set and cure, forming a seamless and robust structure.

Understanding Cast-In-Situ Concrete

Cast-in-situ concrete is a construction method that involves pouring fresh concrete into a specific mould or formwork at the construction site.

Unlike precast concrete, which is cast and cured in a controlled environment before being transported to the construction site, cast-in-situ concrete is mixed and poured on-site. This method offers a high degree of flexibility, allowing for customization and adaptability to the unique requirements of each construction project.

#construction#construction news#civil engineering#building construction#structural engineering#civil#engineering#reinforced concrete#civil construction#concrete

2 notes

·

View notes

Text

The Science of Strong Pools: Shotcrete

When it comes to building a robust and long-lasting swimming pool, one construction technique stands out as a powerhouse in the industry: shotcrete. The science behind shotcrete involves precision, durability, and a deep understanding of materials. In this comprehensive guide, we will explore the fascinating world of shotcrete, shedding light on its construction process, the technology involved, and how it compares to the popular alternative, gunite pools. By the end of this article, you'll have a clear grasp of why shotcrete is the preferred choice for those seeking the utmost strength and resilience in their pool construction.

What is Shotcrete?

Unveiling the Concrete Innovation

Shotcrete, derived from the word "shot," which signifies the forceful projection of concrete, is a construction method that has revolutionized the way we build swimming pools. At its core, shotcrete is a versatile and high-strength material made up of aggregates, cement, and water. Unlike traditional concrete, which is often poured into molds and requires extensive formwork, shotcrete is pneumatically sprayed onto the pool's framework. This application process is what sets shotcrete apart and makes it a preferred choice for pool builders worldwide.

The Shotcrete Advantage

1. Unmatched Strength and Durability

The key to shotcrete's superior strength lies in its application method. During the spraying process, shotcrete is delivered at high velocity, resulting in better compaction and fewer voids in the material. This compaction ensures that the concrete mix is tightly packed, enhancing its structural integrity. As a result, shotcrete pools exhibit exceptional resistance to cracking and are built to withstand the test of time.

2. Faster Construction

Shotcrete's spray application makes pool construction more efficient. Compared to traditional concrete methods, which involve extensive formwork and curing time, shotcrete can significantly expedite the construction process. This not only saves time but also reduces labor costs, making it a cost-effective choice for pool owners.

3. Adaptability to Complex Designs

One of the standout features of shotcrete is its ability to adapt to intricate and custom pool designs. Whether you envision a freeform pool with irregular shapes or a pool with unique structural elements, shotcrete's flexibility allows builders to bring your vision to life with precision.

Gunite vs. Shotcrete Pools: What Sets Them Apart?

Before we delve deeper into the science of shotcrete, it's crucial to address a common point of confusion in the pool construction industry: the difference between gunite and shotcrete. While both are pneumatically applied forms of concrete, there are distinct variations that set them apart.

Gunite Pools: Gunite is a mix of dry sand and cement, which is mixed with water at the nozzle just before it's sprayed onto the pool's framework. While it has been used for decades and offers some advantages, such as cost-effectiveness, it tends to be less dense than shotcrete. As a result, gunite pools may be more susceptible to cracking and water penetration over time.

Shotcrete Pools: Shotcrete, on the other hand, involves premixing concrete materials with water at a controlled ratio before being pneumatically sprayed onto the pool structure. This precise mixing process ensures a denser and stronger material, making shotcrete pools more resilient and durable in the long run.

The Science Behind Shotcrete

The Ingredients: Aggregates, Cement, and Water

At the heart of shotcrete's strength lies its carefully balanced mix of aggregates, cement, and water. Each component plays a vital role in creating a concrete blend that can withstand the challenges of pool environments.

1. Aggregates

Aggregates are the inert materials within the shotcrete mix, typically composed of sand, gravel, or crushed stone. These particles provide volume, stability, and reduce the overall cost of the concrete mix. The selection of aggregates is critical, as it influences the final appearance and strength of the shotcrete pool.

2. Cement

Cement acts as the glue that binds the aggregates together. In shotcrete, Portland cement is the most commonly used type. Its hydration process, where it reacts with water, creates a strong crystalline structure that gives shotcrete its impressive strength.

3. Water

Water serves as the catalyst for the cement's hydration process. Controlling the water-cement ratio is crucial, as an improper balance can lead to weaker shotcrete. Skilled shotcrete technicians meticulously adjust this ratio to ensure the mix's workability and strength.

The Application Process: Pneumatic Spraying

The distinctive feature of shotcrete is its application method. Instead of the traditional pouring of concrete, shotcrete is sprayed onto the pool structure using specialized equipment. This method offers several advantages:

1. Dry-Mix Shotcrete

Dry-mix shotcrete involves pre-blending the dry ingredients (aggregates and cement) and then feeding them into the nozzle of the pneumatic spray gun. Water is added at the nozzle, creating a high-velocity stream of shotcrete material. This approach is often used in swimming pool construction due to its precise control over the mix.

2. Wet-Mix Shotcrete

Wet-mix shotcrete, as the name suggests, involves premixing all the components (aggregates, cement, and water) to create a slurry, which is then pumped to the nozzle. While wet-mix shotcrete can be used in various applications, it may require more effort to control the mix's consistency compared to dry-mix shotcrete.

The Strength of Proper Application

The application of shotcrete requires skilled technicians who understand the intricacies of the process. Shotcrete professionals must control variables such as nozzle distance, angle, and the air pressure used during spraying to ensure the best results. The goal is to achieve maximum compaction and minimal rebound (overspray), leading to a dense, strong pool structure.

The Evolution of Shotcrete Technology

Over the years, shotcrete technology has evolved significantly, leading to even more robust and reliable pool construction. Some notable advancements include:

1. Fiber-Reinforced Shotcrete

Incorporating fibers, such as steel or synthetic materials, into the shotcrete mix enhances its tensile strength. This technology has become increasingly popular for its ability to minimize cracking and improve overall durability.

2. Shotcrete Additives

Additives, such as accelerators or retarders, can be introduced to the shotcrete mix to modify its setting time or improve specific properties. For instance, accelerators are used when rapid setting is required, while retarders slow down the curing process, beneficial in hot weather conditions.

Maintaining Your Shotcrete Pool

Building a shotcrete pool is just the beginning of your pool ownership journey. To ensure its longevity and keep it in pristine condition, proper maintenance is crucial. Here are some tips to help you maintain your shotcrete pool:

1. Regular Inspections

Schedule routine inspections to check for any signs of cracks, leaks, or structural issues. Early detection can prevent more significant problems down the line.

2. Water Chemistry

Maintain proper water chemistry by regularly testing and balancing the pool water. This includes monitoring pH levels, chlorine levels, and alkalinity to prevent corrosion and scale buildup.

3. Cleaning

Regularly clean the pool's surface and the filtration system to prevent algae growth, staining, and clogging.

4. Resurfacing

Over time, shotcrete pools may require resurfacing. Consult with a professional to determine when and how to undertake this process.

Conclusion

In the realm of swimming pool construction, shotcrete stands tall as a testament to engineering innovation and material science. Its precise application, coupled with a meticulously balanced mix, ensures that shotcrete pools not only withstand the test of time but also offer unmatched strength and durability. As you embark on your pool-building journey, understanding the science behind shotcrete can help you make an informed decision about the construction method that will best serve your needs. With shotcrete, you're not just building a pool; you're crafting a structure that will provide joy and relaxation for years to come.

4 notes

·

View notes

Text

Construction Technology

Buildings are constructed by SJ Contracts using modern technologies. Technology has made great progress in the building sector. In our construction company, the following new technologies are frequently used:

1.Building Information Modelling (BIM): BIM is a digital representation of a building's physical and functional characteristics. It allows architects, engineers, and contractors to collaborate effectively by creating a 3D model of the building. BIM facilitates better visualization, clash detection, and coordination among different disciplines, resulting in improved project efficiency and reduced errors.

2.Prefabrication and Modular Construction: Prefabrication involves constructing building components off-site in a controlled environment, while modular construction employs pre-built modules that are manufactured and assembled off-site. Both methods offer advantages such as faster construction time, reduced material waste, enhanced quality control, and improved site safety. Prefabrication and modular construction enable streamlined workflows and increased efficiency.

3.Virtual Reality (VR) and Augmented Reality (AR): VR and AR technologies enhance visualization and design review processes. VR creates immersive virtual environments, allowing stakeholders to experience the building design before construction begins. AR overlays digital information on physical spaces, aiding in tasks like on-site measurements, material placement, and clash detection. Both technologies improve communication, decision-making, and design coordination.

4.Formwork: Formwork is the temporary structure used to support the construction of concrete elements, such as walls, columns, and slabs, until they gain sufficient strength. SJ Contracts may employ modern formwork systems, such as modular or adjustable systems, to optimize efficiency and reduce labor time in concrete construction. These systems offer flexibility, ease of use, and reusability, leading to faster construction cycles.

By utilizing these technologies, SJ Contracts can achieve higher levels of efficiency, accuracy, and productivity in their construction projects. The adoption of BIM improves collaboration and reduces rework, while prefabrication, modular construction, and modern formwork techniques contribute to faster and more controlled construction processes. VR and AR technologies enhance design visualization and coordination, leading to improved project outcomes.

#SJcontracts #construction #constructioncompany #builders #buildingconstruction #enineering #constructionequipment

2 notes

·

View notes

Text

High-Quality Permanent Concrete Formwork by Santana Stud Welding Looking for reliable permanent concrete formwork solutions in Australia? Santana Stud Welding delivers durable, efficient, and expertly engineered formwork systems ideal for modern construction projects. Trusted by builders and developers nationwide, our systems ensure structural integrity and long-term performance.

Proudly listed on top10.australia247.info, Santana Stud Welding is recognised as one of the top providers in the industry. Whether you're working on commercial high-rises or large-scale infrastructure, our team ensures your project meets the highest standards.

Visit our website to learn more and request a quote today!

https://santanastudwelding.com.au/permanent-concrete-formwork/

#permanent concrete formwork#stud welding#construction solutions#Santana Stud Welding#concrete formwork Australia#top10.australia247.info#structural formwork#building systems

0 notes

Text

Guide to Plinth Beam Construction with Ready Mix Concrete

Concrete Mixing and Compacting

Using ready mix concrete for plinth beam construction offers precision and consistency. Proper compaction eliminates air pockets, improving the overall strength and density of the structure. Opt for high-performance cement like Prism Champion to achieve these results effortlessly.

How to Build a Plinth Beam?

Building a plinth beam involves several critical steps:

Excavate the foundation trench to the desired depth

Place reinforcement bars as per the design

Set up shuttering and ensure it’s secure

Pour the ready-mixed concrete into the formwork

Compact the concrete to eliminate air voids

Cure the structure for a specified duration to ensure strength development

Quality Inspections During Plinth Beam Construction

Regular quality checks ensure the durability and stability of the plinth beam:

Verify that materials meet design specifications

Check alignment and reinforcement placement

Ensure proper curing for sufficient hydration of concrete and cement

1 note

·

View note

Text

Plastic Formworks | Nova Formworksblr

Nova Formworksblr offers durable and reusable Plastic Formworks designed for efficient and cost-effective construction. Unlike traditional materials, Plastic Formworks are lightweight, easy to handle, and resistant to water, corrosion, and chemicals. Ideal for all types of concrete structures, they ensure a smooth finish and fast assembly. Nova Formworksblr provides innovative shuttering solutions that reduce labor and maintenance costs while increasing productivity. Choose Plastic Formworks for long-lasting performance and sustainable building practices.

0 notes

Text

Stylish modern apartments designed for contemporary living. Featuring spacious balconies, lush landscaping, and a vibrant community atmosphere—perfectly located for convenience, comfort, and lifestyle. Ideal for families and professionals alike.

0 notes

Text

Thermal Challenges in Construction: Navnirman’s Solutions for Hot Weather Building

Summary

Summer construction brings blistering heat that compromises not only crew safety but also structural integrity. Rapid water evaporation disrupts concrete curing, resulting in cracks and costly delays. Navnirman’s innovative thermal formwork systems bring a proven, heat-smart solution by controlling temperature, reducing water loss, and delivering the optimal curing conditions even in blistering sun. Constructed from durable, heat-resistant materials and rapid installation designs, these systems speed up project schedules, protect crews, and extend the life of structures. Navnirman is revolutionizing the way new builders conquer hot-weather construction challenges — safely, economically, and with confidence.

When the Heat Is On: The Real Dangers of Summer Building

In the hot weather construction world, there aren’t many more urgent things than cooling down your concrete. As the temperature goes up, water evaporates more quickly, which disrupts curing times, strength, and surface finish. Not ideal if you’re constructing a bridge, a foundation, or a skyscraper. It equals cracks, less durability, and a greater likelihood of having to begin all over again. Eek.

And then there’s the human factor. Crews battling the sun tend to get fatigued and make errors — not the best mix when you’re racing against time and saving lives.

The Navnirman Advantage: Formwork That Keeps Cool Under Pressure

Fortunately, Navnirman thermal formwork systems have been engineered to counter such hot conditions. They’re no ordinary molds. They’re specifically designed to control temperature, reduce water loss and offer the perfect conditions for curing — no matter the intensity of the sun during summer.

Consider it air conditioning for your concrete. By keeping the micro-environment in balance, these formwork systems allow the structure to be set consistently and more solidly. That translates to better performance, less delay, and less rework due to heat-sustained stress.

Smarter Materials = Cooler Results

One of the success story players? Heat-resistant building materials. Navnirman uses materials which also naturally resist the conduction of heat, thereby insulating your concrete from the full impact of the temperature highs. This low-tech-high-idea design principle is a giant factor in thermal management in buildings.

With formwork that does not retain and give off heat like old metal or wood alternatives, Navnirman allows your concrete to experience a stable environment in which to cure. That means less trouble with surface cracks, lower internal stresses, and extended structural life — even in blistering summer temperatures.

Repairing Summer Construction Issues, Pour by Pour

Let’s face it: summer construction issues don’t start with the concrete. Worker safety, material performance, and site scheduling all twist a little with heat. But when your formwork system is working with you instead of against you, that twist isn’t necessarily a full-blown snag.

Navnirman’s module formwork facility covers not only temperature control but also easy installation and striking. Rapid cycles mean less exposure to the elements and more freedom to reschedule when the weather demands. That’s a boon any site manager will appreciate — especially when the weather forecast keeps climbing above 40°C.

Designed for Builders, Not for Buildings

At the end of it all, a smart formwork system not only protects your concrete — it protects your crew, your schedule, and your bottom line. Navnirman solutions are designed with real jobsites in mind. They are easy to use, reusable, and scalable to projects of all sizes.

From single-family homes to large-scale infrastructure projects, these formwork systems are enabling contractors worldwide to confront thermal construction challenges head-on and with assurance, each and every time. Because when your equipment is engineered to beat the heat, so are you.

Wrapping It Up Without Overheating

Summer construction does not always have to be a pressure cooker. Navnirman’s creative solution to hot weather construction assists you in beating the heat, sidestepping the hassle, and staying on schedule, on time, and on target. By implementing Navnirman thermal formwork and leaning into intelligent thermal management by construction, you’ll not only be extending the life of your building, but also the working conditions of your people on site. It’s a win-win for your team, your customer, and your building — no sunburn needed. Discover how Navnirman is shaping the future of heat-smart construction at Navnirman.in

0 notes

Text

Types of Cement Used in Construction and Their Applications

Cement is the key binding material in construction, playing a critical role in the strength, durability, and longevity of any structure. However, not all cement is the same. Different types of cement are formulated for specific uses and performance requirements. Choosing the right type of cement is essential to ensure safety, efficiency, and cost-effectiveness in construction.

This article explores the major types of cement used in construction along with their specific applications.

1. Ordinary Portland Cement (OPC)

Description: Ordinary Portland Cement is the most widely used cement type. It is available in three grades: 33, 43, and 53, depending on compressive strength after 28 days.

Applications:

Residential and commercial buildings

Pavements and bridges

General-purpose concrete and mortar works

2. Portland Pozzolana Cement (PPC)

Description: PPC is made by blending pozzolanic materials like fly ash with OPC. It has better resistance to chemical attacks and reduced heat of hydration.

Applications:

Plastering and masonry work

Marine structures

Sewage and drainage systems

Mass concrete work like dams

3. Rapid Hardening Cement

Description: This cement gains strength faster than OPC, especially during the first few days. It is ideal when early removal of formwork or quick project turnaround is needed.

Applications:

Road repairs

Precast concrete work

Cold weather concreting

4. Sulphate Resisting Cement

Description: This type is designed to resist sulphate attacks. It contains a lower percentage of tricalcium aluminate.

Applications:

Foundations in sulphate-rich soils

Marine structures

Sewage treatment plants

5. Quick Setting Cement

Description: Quick setting cement sets faster than OPC, making it suitable for works where setting time is crucial.

Applications:

Underwater construction

Cold regions

Grouting work

6. Low Heat Cement

Description: This cement produces less heat during the hydration process, reducing the risk of cracking in large structures.

Applications:

Dams

Mass concrete works

Retaining walls

7. White Cement

Description: White cement is similar to OPC but is made from raw materials with low iron content. It has high aesthetic value and is used for decorative purposes.

Applications:

Wall putty and tiles

Architectural finishes

Precast decorative products

8. Portland Slag Cement (PSC)

Description: PSC is made by mixing granulated blast furnace slag with OPC. It provides enhanced durability and chemical resistance.

Applications:

Marine and coastal structures

Industrial foundations

Mass concreting

9. High Alumina Cement

Description: High in alumina content, this cement is known for its high early strength and resistance to chemical attacks.

Applications:

Chemical plants

High-temperature structures

Sewer linings

10. Expansive Cement

Description: This cement expands slightly on setting, helping reduce shrinkage cracks.

Applications:

Grouting

Repair works

Pre-stressed concrete

Conclusion

Understanding the types of cement and their applications ensures that the right product is used for the right job. This not only improves structural integrity but also enhances durability, efficiency, and sustainability.

When quality Cement and performance matter, always choose trusted cement brands like JK Cement, which offer a wide range of certified products suitable for all construction needs.

0 notes